WI-Appleiviyoukusetshenziswa kobuchwepheshe bokushaja okungenantambo ku-iPhone 8, itis washaya yonke imboni. Njengomthengi ojwayelekile, ngaphezu kokusebenzisa amashaja angenantambo nsuku zonke, uyakwenzabonaKanjaniiyakwenzaIshaja engenantambobeKwenziwe? Manje siyathathale khasiInqubo yokucubungula yeshaja engenantambo.Silandele ezinyathelweni zami futhi ngizokukhombisa inqubo yokukhiqiza yokushaja okungenantambo emhlanganweni weLantaisi.

Ukushaja okungenantambo kuhlukaniswe izingxenye ezimbili: ibhodi yesekethe yangaphakathi nengxenye yangaphandle. Inqubo yokukhiqiza yokushaja okungenantambo izokwethulwa ngokuningiliziwe kulezi zinhlangothi ezimbili.

Okokuqala, ukuthengisa kwethu kanye namakhasimende akhe baxhumana nomunye ukuthola ukwakheka komkhiqizo kanye nezidingo zokusebenza. Ngokulandelayo, uMnyango weLanaisi wezobuchwepheshe uzokwakha ibhodi yesekethe langaphakathi, futhi umnyango womkhiqizo uzokwakha isakhiwo segobolondo.

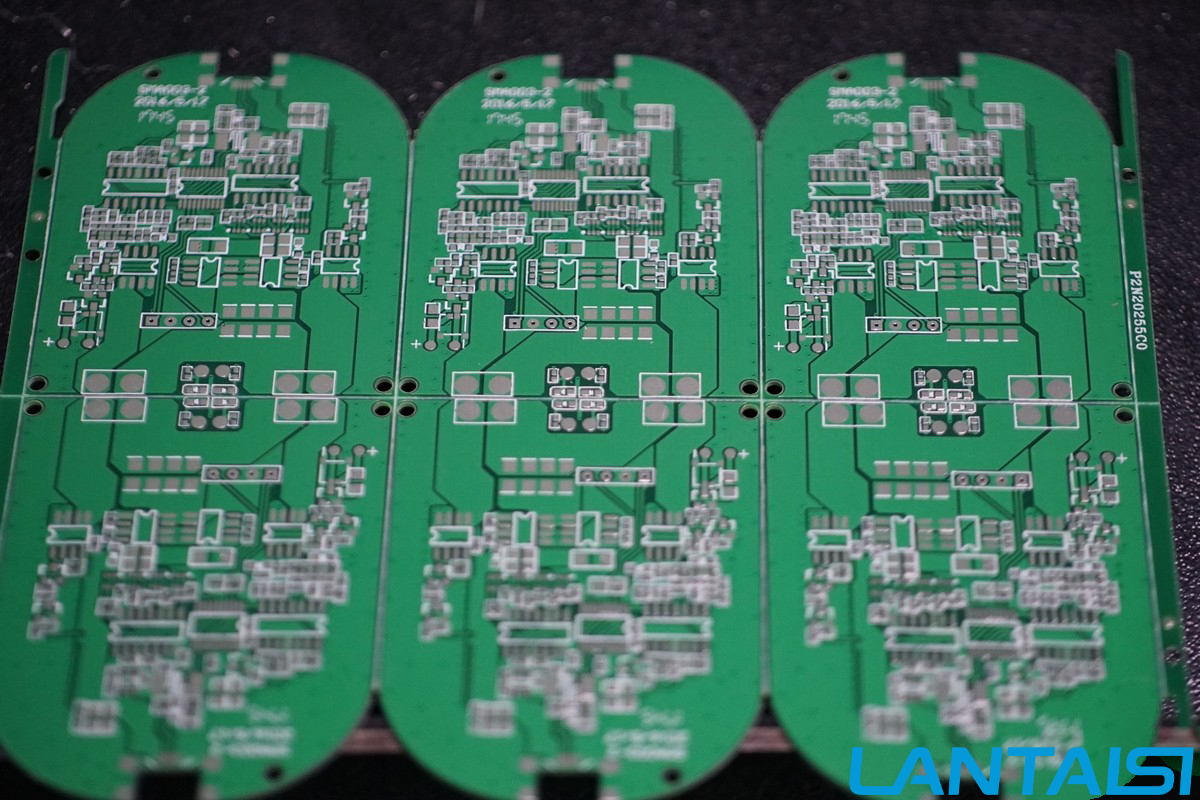

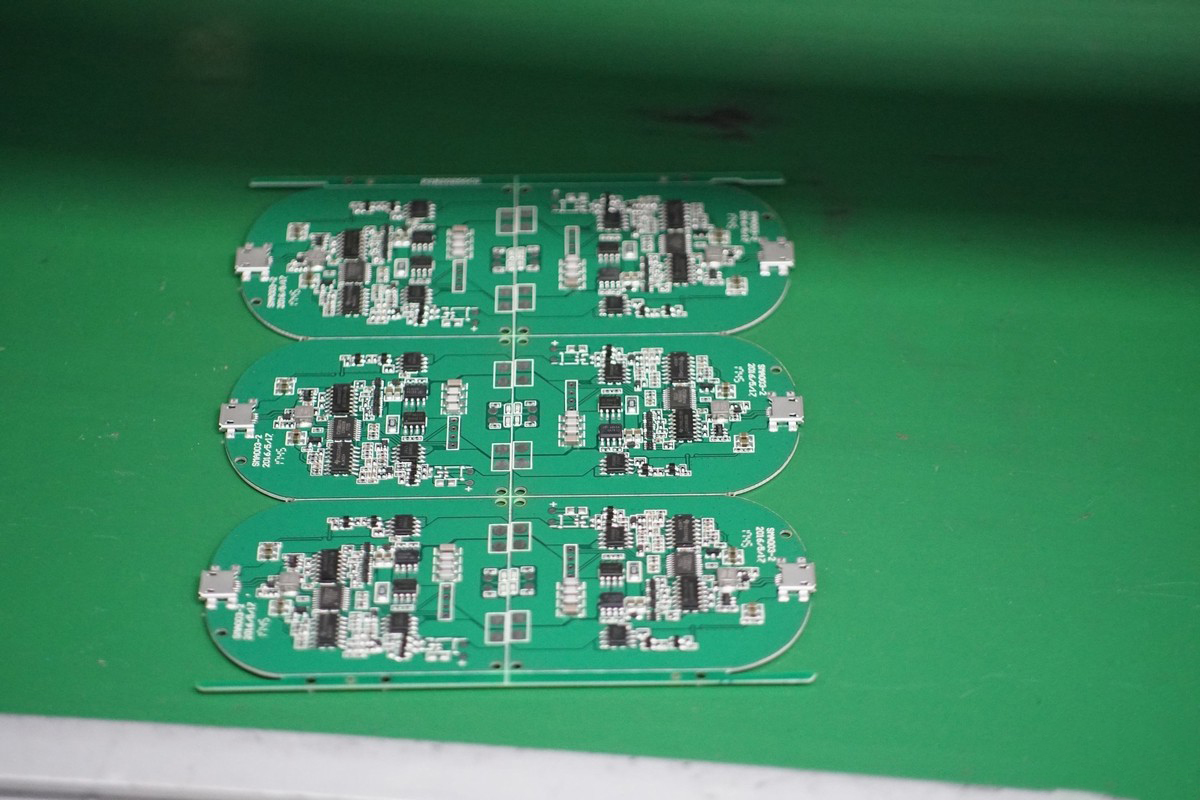

Isinyathelo 1:Lesi sithombe esingenhla siyibhodi elingenalutho ngaphandle kwezinto ze-elekthronikhi. Okokuqala, izofakwa emshinini wokuphrinta ozenzakalelayo ngokugcwele futhi ipendwe ngesendlalelo sokunameka umthengisi. I-solder paste ihlanganiswa ne-powder ye-soler, i-flux, nezinye izinto ezisetshenziswayo kanye nama-thixotropic agents. Kungabonakala kusuka esithombeni leli bhodi yeSifunda elingenantambo elingenantambo linezakhi ezingaphezu kwama-30.

(Isithombeni ngenhla sibonisa umshini wokuphrinta ozenzakalelayo ozenzakalelayo.)

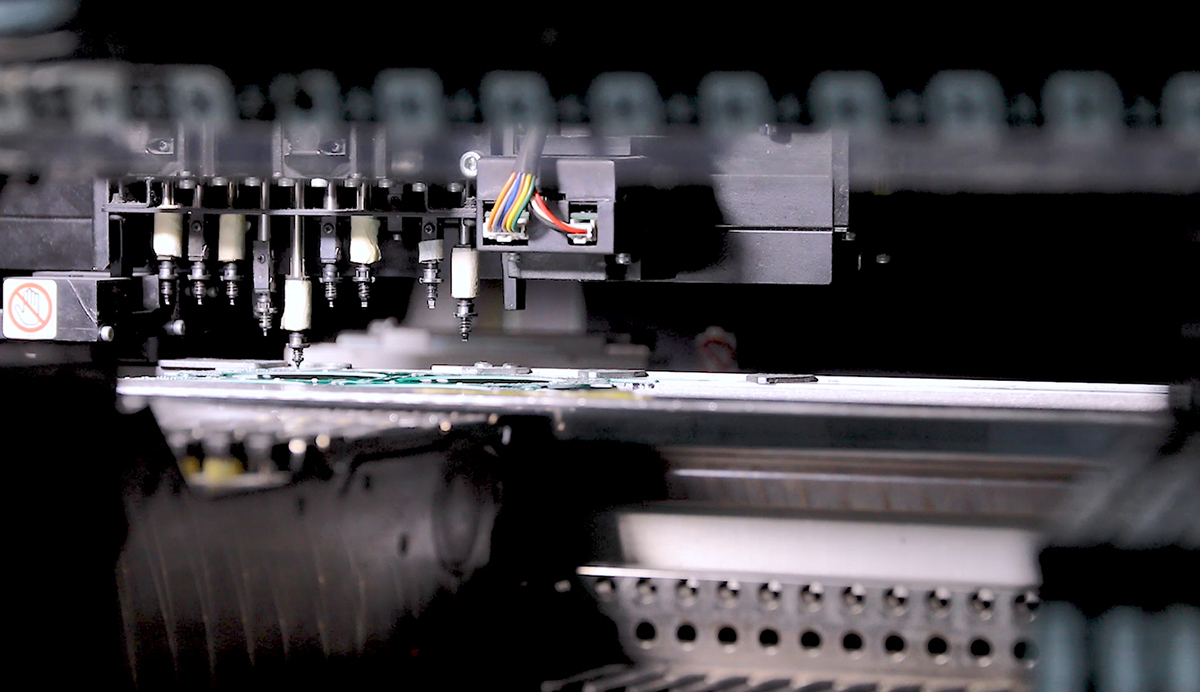

Isinyathelo 2:Ngemuva kwalokho faka inqubo elandelayo: I-SMT Patch. I-SMT imele ubuchwepheshe beNtaba ye-Surface futhi isetshenziswa kabanzi embonini yama-elekthronikhi. Isetshenziselwa ikakhulukazi ukufakwa kwezinto ze-elekthronikhi ngaphandle kokuhola noma okuholayo okufushane.

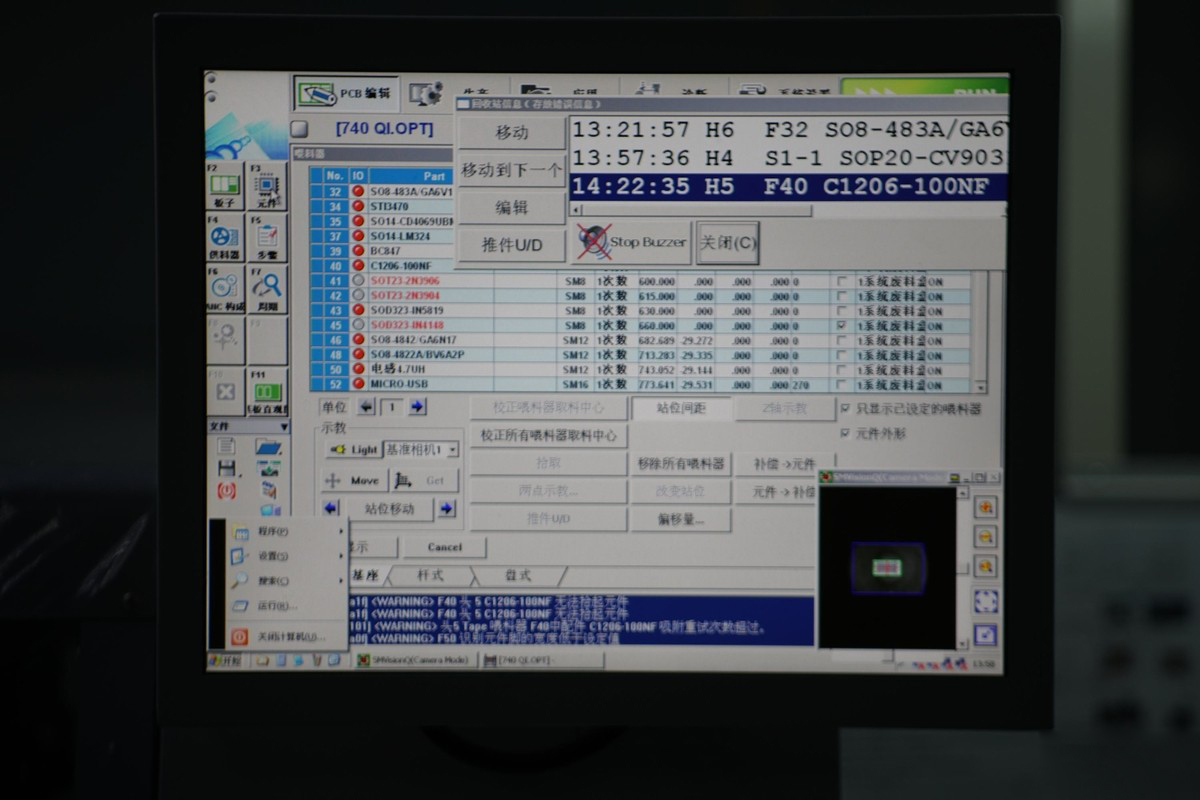

Isinyathelo 3:Umshini wokubekwa we-SMT ufaka futhi ulungisa ama-chip, amelana nama-capacitors, ama-capacitors, ama-inductors nezinye izingxenye ebhodini lesekethe elihlanganiswe ne-solder paste ngokulandelana. Umshini ngamunye wokubeka isivinini esiphezulu uzolawulwa yikhompyutha encane. Onjiniyela bazokwakha futhi bahlele inqubo yokusebenza esethiwe ngokuya ngezinto ezibonakalayo zokushaja kwe-charliity board, okuthuthukisa kakhulu ukunemba kwebhodi yokubekwa.

Isinyathelo 4:Lesi sithombe esingenhla sibonisa ukusebenza kokujikeleza kwe-Reflew yenqubo yokuvikela imvelo engenamkhawulo. Okwesokudla okulungile kungukukhohlisa imishini yokuthengisa ngokushisa kwangaphakathi kwama-degree angaphezu kwama-200. I-PCB ingezansi ngemuva kokuxubha, ukugoqa, futhi ukukhombisa ukuthengisa sekuyi-PCBA ephelele. Ngalesi sikhathi, i-PCBA idinga ukuhlolwa ukuthola ukuthi imisebenzi yengxenye ngayinye iyinto ejwayelekile.

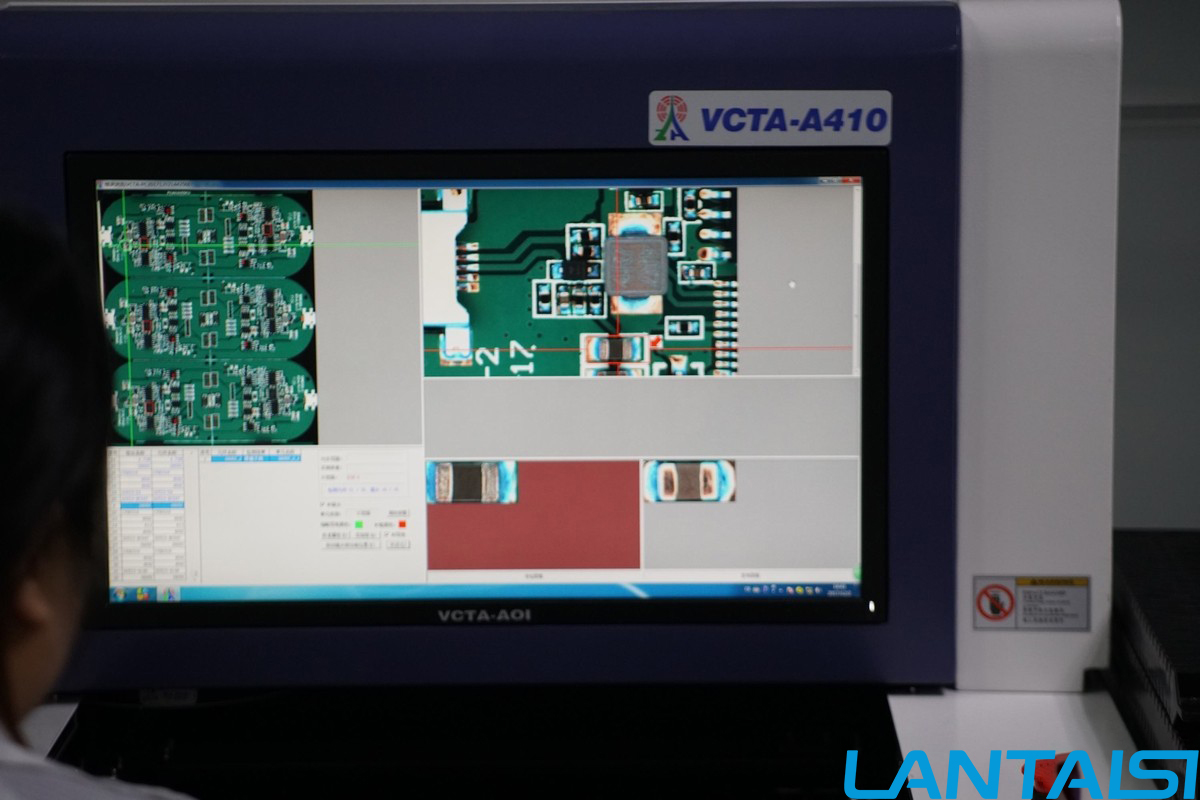

Isinyathelo 5:Lesi sithombe esingenhla sibonisa ukusetshenziswa kwe-AOI ezenzakalelayo Detector ukubheka i-PCBA. Ngamashumi wezikhathi zokukhulisa, ungahlola ngokucacile ukuthi ngabe kukhona yini izinkinga ezinjengokuthengisa okungamanga kanye nokuthengisa okungenalutho ngesikhathi senqubo yokubekwa kwe-chip kanye nokumelana ne-capsacitance.

Isinyathelo 6:Ibhodi le-PCBA eliqeqeshiwe lizothunyelwa kwinqubo elandelayo - i-welding coil ye-transmitter.

Isinyathelo 7:I-Welding Coil i-Transmitter idinga ukusebenza ngesandla. Kungabonakala esithombeni esithi uchwepheshe ane-wristband eluhlaza okwesibhakabhaka esandleni sakhe sobunxele. Kukhona ucingo kule wristband elisekelwe ukuvikela ugesi womzimba wabantu ukuthi angenise i-chip enokunemba ephezulu.

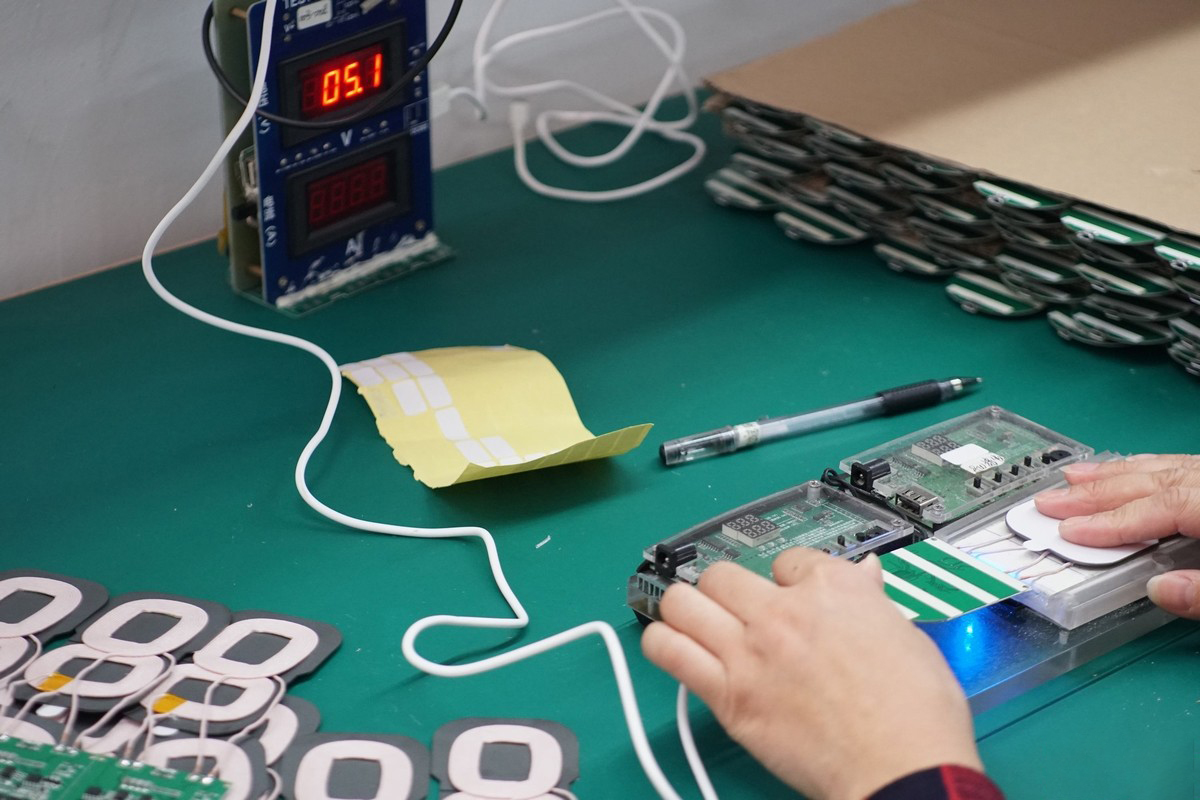

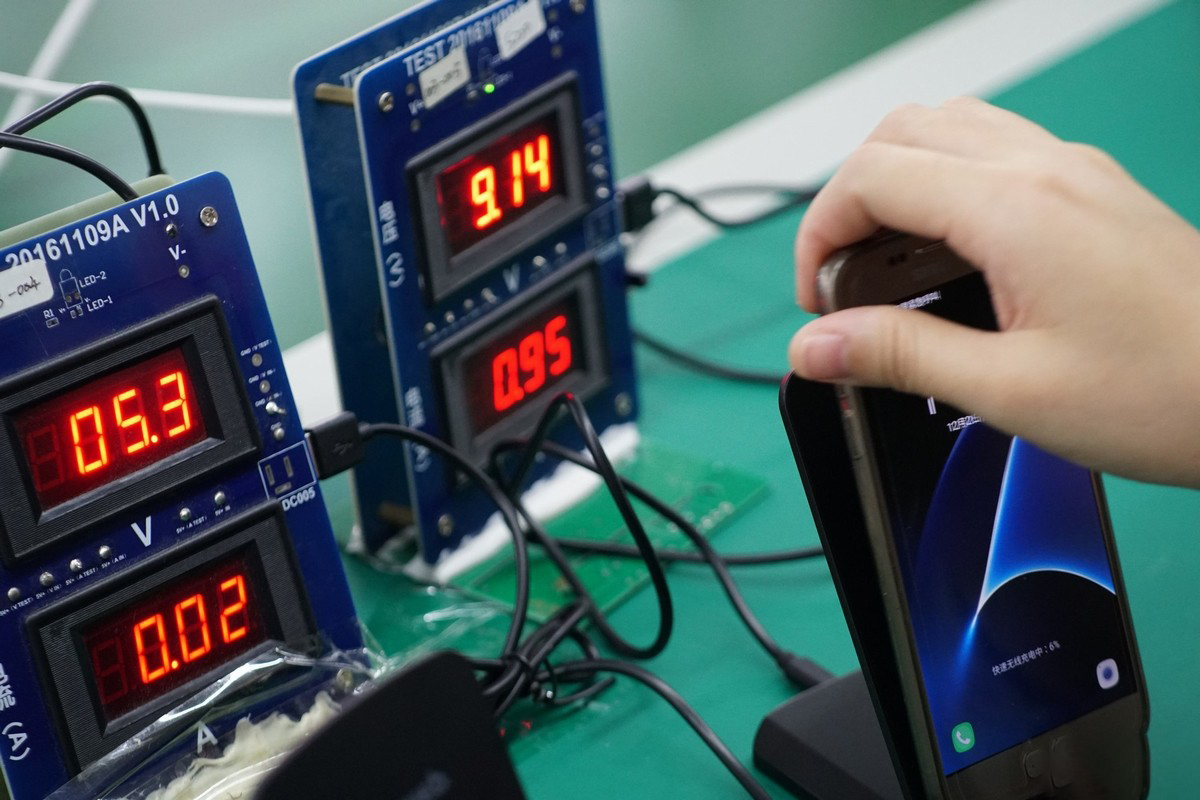

Isinyathelo 8:Okulandelayo, hlola ukuthi i-Transmitter Coil Board ingasebenza ngokujwayelekile. Lapha, izimo zokusebenza kwezinto ezisebenza ngokufaka ezihlukile zizohlolwa.

(Lesi sithombe ngenhla sibonisa i-voltage futhi okwamanje ishaja lapho ishaja engenantambo ishaja ngokushesha, 9V / 1.7a.)

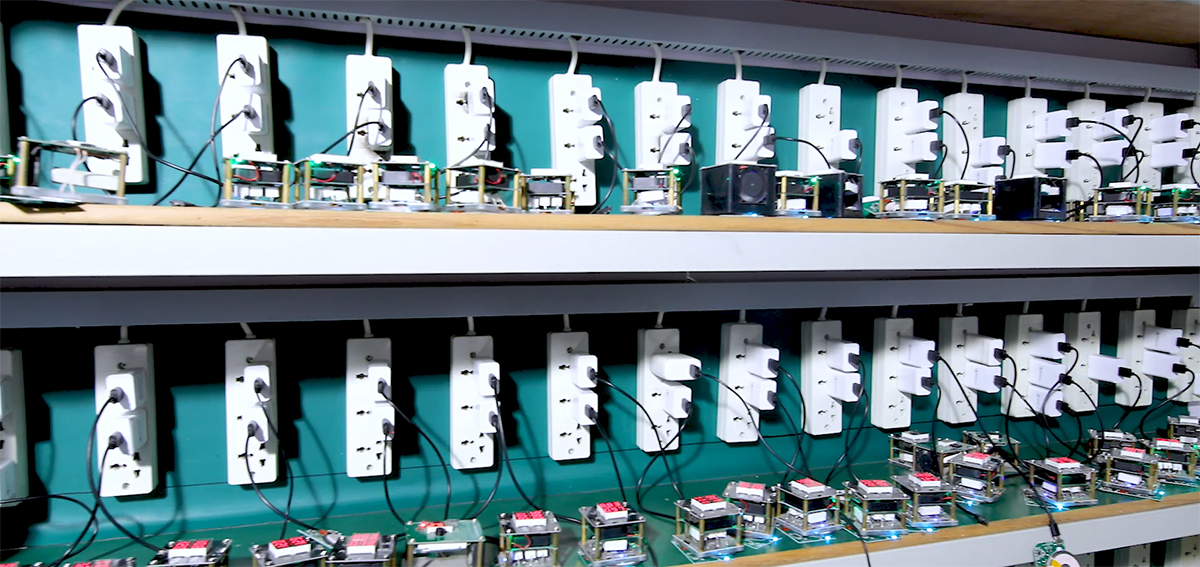

Isinyathelo 9:Le nqubo isivivinyo sokuguga. Ishaja ngalinye elingenantambo elifanelekile lidinga ukuhlolelwa amandla futhi lilayishe ngaphambi kokushiya ifektri, ukuze imikhiqizo engenaphutha ingeniswe ngaphambi kwesikhathi senqubo yokuhlola; Labo abadlulisela isivivinyo sokuguga bazongena kwinqubo yomhlangano, futhi abanephutha bazoyikhipha ekuxazululeni inkinga. Ngokusho kwe-Factory Engineer, ukushaja kwe-wire engenantambo eyodwa kudinga ukuhlolwa kokuguga okungu-2, ngenkathi ikhoyili ebilinayo ingamahora ama-4.

Lesi sithombe esingenhla sikhombisa ukushaja kwe-wireless ukushaja ibhodi ngemuva kokuhlolwa kokuguga, futhi ucezu ngalunye luhlelwe kahle. Labo abanezakhi ze-elekthronikhi babhekana nokugwema ukulimaza ngesikhathi senqubo yokugoqa.

Isinyathelo 10:Lungisa imodyuli ye-Transmitter ku-Wireless Charger Shell nge-3M glue.

Lesi sithombe esingenhla sibonisa ishaja engenantambo eqediwe engenantambo esehlangene futhi isizolinda isixhumanisi esilandelayo sombuso.

Isinyathelo 11:Bopha izikulufo.

Ishaja elingenantambo elimile eline-wireless nge-dual-coil ukushaja kuqediwe.

Isinyathelo 12:Ukuhlolwa komkhiqizo okuqediwe ngaphambi kokuthumela. Lesi sixhumanisi sisetshenziselwa ukuqeda ukuhambisana kokushaja okungenantambo, futhi siqinisekise ukuthi umkhiqizo wokushaja okungenantambo ufika esandleni somsebenzisi ungaba nakho okufanayo kokusebenza njengeshaja yokuqala.

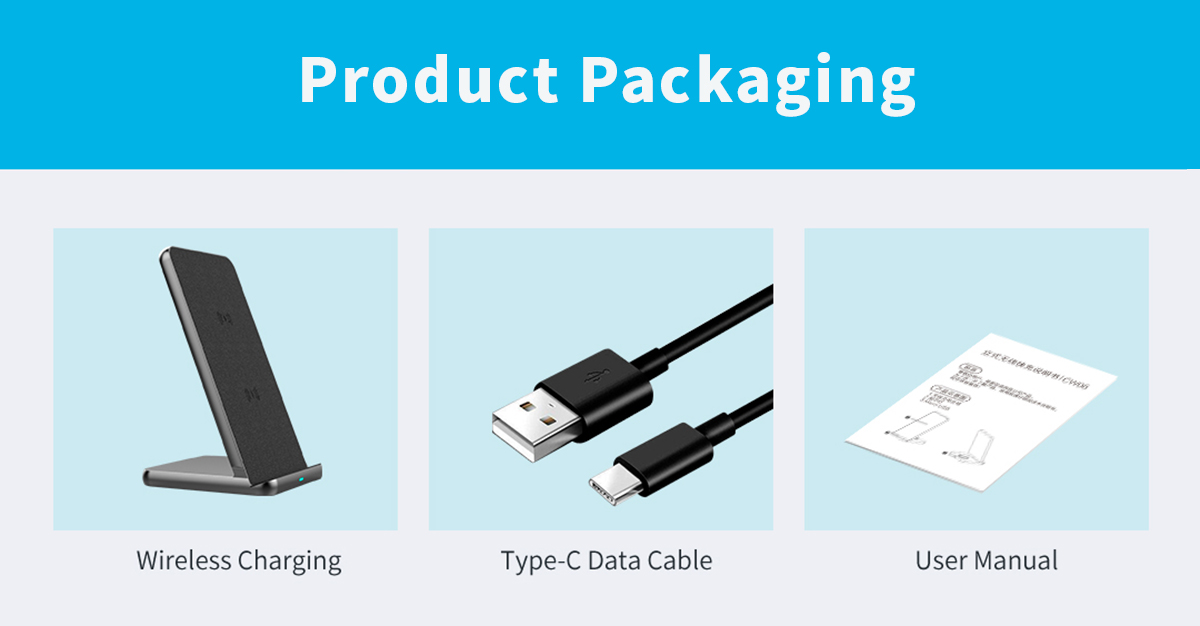

Isinyathelo 13:Beka umkhiqizo esikhwameni se-PE, usibeke kukhebula lencwadi ethi Manual, Type-C, bese ulipaka ebhokisini, bese ulipaka bese ulinda ukuthunyelwa.

Lokhu okungenhla kuyinqubo ephelele yokukhiqiza yokushaja okungenantambo. Ngamafuphi, kungukuphrinta okungenalutho kweBhodi, i-SMT Patch, ukukhombisa ukuthengisa, ukuhlola ikhoyili ye-PCBA, ukuhlolwa, ukuhlolwa kokuguga, ukugcwaliswa kwegobolondo, ukufakwa komkhiqizo okuqediwe.

(Yebo, ukuze uqinisekise ukuphepha nokwethembeka kwemikhiqizo yethu, sizokwenza ukuhlola isikhunta, ukuhlolwa kokusebenza nge-elekthronikhi, ukuhlolwa kokubukeka, njll., Ngokushaja okungenantambo.)

Ngemuva kokuyifunda, ingabe unokuqonda okuningiliziwe kwenqubo engaqondakali yokukhiqiza yokushaja? Ngemininingwane engaphezulu, sicela uxhumane neLantaisi, sizoba senkonzweni yakho kungakapheli amahora angama-24.

Isikhathi sePosi: Sep-25-2021